UK's Leading Timber Supplier

Sustainable Timber Experts (UK) - Founded in 2017, Timber Focus has rapidly grown to become one of the UK’s leading importers of speciality timber products, sourced from the world’s most reputable sawmills. We offer the most comprehensive range of timber products in the UK including cladding, trim, decking, fencing, shingles, shakes, screens, fasteners, wood care and pre-finishing service.

Timber cladding is an increasingly popular choice for finishing the outside of commercial and domestic properties. Otherwise known as timber weatherboarding or timber siding, it is an attractive and economical way to finish the exterior of both old and new buildings.

Timber Focus are the leading supplier of speciality timber decking products in the UK. With a range of hardwood timber decking products suitable for all requirements. Products include our stunning clear grade Western Red Cedar, Siberian Larch and a variety of high quality hardwoods.

With a number of profiles available at lengths to suit your needs in stock, Timber Focus can provide you with the best quality hardwood decking solutions in the UK.

Timber Focus stock a wide range of timber cladding from the world's leading timber processing companies including Western Red Cedar, Siberian Larch, ThermoWood and Accoya. Our exterior wood cladding range, most of which is either FSC or PEFC certified, has been carefully selected to ensure that it meets the highest standards of quality at the most competitive prices. Consider our enhanced services such as fire treatment and factory coating.

For an environmentally friendly building material, timber cladding is a clear leader. Using external timber cladding for traditional and contemporary building projects is becoming increasingly popular amongst architects and designers for both major commercial buildings and smaller domestic properties.

External timber cladding can enhance the look of a variety of buildings and is available in a range of finishes and profiles to suit every construction type. It is used extensively to clad brick and mortar, timber frame buildings, and increasingly in prefabricated modular buildings. It acts as a weatherboard or ‘rainscreen’ to the wall behind and has the additional benefit of protecting and concealing external insulation on walls. External insulation and wood cladding can deliver the full thermal performance of new buildings or improve the thermal performance of existing buildings. Choosing the right timber for each job is key, considering the expected surface life alongside the required maintenance schedules of the wood. We have a large selection of external timber claddings from SertiWOOD® Painted claddings, DragonWOOD®, Thermowood, Siberian larch, Western Red Cedar, Fire Retardant Cladding, PreAged Old look, Preweathered Silvery Grey Siberian larch, Charred wood in Larch Accoya and Kebony.

Siberian Larch Cladding

Siberian Larch is a very durable, cost effective timber ideally suited for cladding and fencing applications. This slow growing Softwood gives a high density hard finish perfect for external use. Straw coloured in appearance and fading to silvery tone over time. Sourced from well managed forests in Northern Europe our stocks are FSC® certified. This specie comes with occasional knots

Western Red Cedar Standard Slatted Screen Fence Kits 19 x 38mm

- Easy to build slatted screens

- All you need to create a Western Red Cedar slatted screen fence

- Choose the linear metre option which suits you best

- Surfaced on 1 side and 2 edges. Lightly textured on reverse side

- Kit includes Canadian Western Red Cedar standard battens, posts and nails

- Designed to create a 1.83m high fence

Top of Form

Description

Cowichan Gold slatted screen boards are produced from fine-grained, old-growth, exceptional Western Red Cedar wood fibre sourced from the coastal regions of British Columbia.

They are manufactured to the highest production standard in the industry by Terminal Forest Products, a family-owned and operated company, which has built an enviable reputation throughout the sawmill industry as a leader in quality and consistency.

Terminal's most exclusive brand, Cowichan Gold, is almost entirely knot free and virtually all heartwood, making it one of the highest quality Western Red Cedar screening products available anywhere.

Recommended Nails: 50mm Flat Head Stainless Steel Annular Ring Nails

Recommended gap between boards: 18mm

At a glance

- Made from kiln-dried, Canadian Western Red Cedar.

- Very popular for various types of fencing, railing and screens

- Highest quality wood fibre with virtually no knots

- Highly durable material

- Light weight for easy installation

Please ensure when ordering that you make an allowance for wastage. We recommend adding an additional 10-15% over and above your initial requirements.

Bottom of Form

Please click images to view

Create an architectural look that provides visually interesting shadow lines and texture.

Slatted screens can enhance a garden's style with a contemporary look:

- Creates a surface with ever changing patterns of light and shadow

• Provides a wonderful backdrop for plants and foliage

• Truly versatile - slats available in a variety of widths and length allow you to create unique visual rhythms and proportions

• Simple installation methods transforms landscapes instantly

• Provide privacy without complete obstruction

• Horizontal boards are more effective at screening against wind than a solid fence

• Can provide shade without sacrificing natural light

• Define boundaries within the garden - separate relaxation areas from storage space.

A well designed and carefully built screen can provide a wonderful focal point for an outdoor space, so choosing the correct material is paramount. No other material compares to Western Red Cedar in terms of appearance, with beautiful warm colours and tight grain patterns providing a stunning natural material.

Stability is also key for slatted screens. To maintain the crisp, clean lines that are essential to the overall look of the screen it is important to choose a material that is less susceptible to warping or twisting. Being one of the most stable wood species on the planet, Western Red Cedar fits the bill perfectly.

Timber Focus Ltd are becoming the UK's favourite decking supplier- offering a vast range of options both treated and untreated.

Trade and retail orders are welcome in any quantity. Our boards are available in various hardwood and softwood species, such as English Oak, English Larch, Continental Redwood, Siberian Larch and Redwood Thermowood - allowing us to offer what we believe is the most complete and exclusive range of decking boards in the UK.

All boards and components are sawn, dried and machined on site. Retaining complete control of the manufacturing / machining process enables full oversight of quality control. Another unique part of the Timber Focus Ltd offering is a vast variety of lengths and section sizes enabling construction without cutting in most cases.

We offer an in-house crane delivery service, that covers most of the UK. When you place an order with Timber Focus Ltd we will look after you from the beginning of the process to end.

Timber focus's Western Red Cedar makes perfect sense:

- Highly durable and long lasting

• Exceptional stability means Cedar boards remain flat and straight

• Clear grade Western Red Cedar offers unrivalled beauty

• Being light in weight, Cedar is easy to cut and handle on site, reducing build time

• Beautiful tones and grain patterns

• A proven performer in all types of climate, so its a natural product you can rely upon

Surface Texture

Cowichan Gold Boards are smooth on one side and both edges, and have a SAWTEX® textured finish to the rear.

Silva Select Prestige VG Western Red Cedar Boards

From £4.32 per linear metre (ex VAT)

Cascadia Western Red Cedar Boards

From £1.80 per linear metre (ex VAT)

Silva Select Prestige VG Western Red Cedar Rainscreen Cladding

From £4.32 per linear metre (ex VAT)

Silva Select Prestige VG Western Red Cedar Tongue & Groove Cladding

From £4.32 per linear metre (ex VAT)

Silva Select Prestige VG Western Red Cedar Microline Channel Cladding

From £4.32 per linear metre (ex VAT)

SILVALarch™ V-Joint Weatherboard Cladding

From £2.51 per linear metre (ex VAT)

Western Red Cedar No. 2 Clear V-Joint Cladding 18 x 137mm

Per Linear Metre:

£5.84

(exc VAT)

Timber Deck Boards

Per Linear Metre:

£3.87

(exc VAT)

SILVALarch™ Channel Cladding

From £1.38 per linear metre (ex VAT)

Accoya 15 x 145mm Fineline Channel Cladding

Per Linear Metre:

£7.45

exc VAT)

Accoya 15 x 145mm Chamfered Channel Cladding

Per Linear Metre:

£7.45

(exc VAT)

Neolife Cladding

Per Linear Metre:

£11.66

(exc VAT)

ThermoWood® Channel Cladding - 20 x 118mm

Per Linear Metre:

£2.34

(exc VAT)

ThermoWood SAWtex Channel Cladding - 20 x 118mm

Per Linear Metre:

£2.74

(exc VAT)

Silva Select Western Red Cedar Tongue & Groove Cladding - 18 x 94mm

Per Linear Metre:

£3.87

(exc VAT)

Cascadia Western Red Cedar Tongue & Groove V-Joint Cladding - 19 x 137mm

Per Linear Metre:

£3.54

(exc VAT)

SILVALarch™ Tongue & Groove V-Joint

From £1.38 per linear metre (ex VAT)

ThermoWood Tongue & Groove Cladding - 20 x 118mm

Per Linear Metre:

£2.34

(exc VAT)

Western Red Cedar SAWtex V-Joint Cladding

From £2.69 per Linear Metre (ex VAT)

Silva Select Western Red Cedar Rainscreen Cladding - 18 x 94mm

Per Linear Metre:

£3.87

(exc VAT)

SILVALarch™ Rainscreen Cladding

From £1.38 per linear metre (ex VAT)

SILVALarch™ Bevel Cladding

From £1.38 per linear metre (ex VAT)

Cascadia Western Red Cedar Rebated Bevel Cladding - 18 x 187mm

Per Linear Metre:

£3.38

(exc VAT)

DuPont™ Tyvek® HouseWrap®

£41.58

(exc VAT)

SILVALarch™ Shiplap Cladding

From £1.38 per linear metre (ex VAT)

Silva Select Western Red Cedar Boards - 18 x 94mm

Per Linear Metre:

£3.87

(exc VAT)

Western Red Cedar Trim Boards 19 x 38mm

Per Linear Metre:

£2.25

(exc VAT)

SILVALarch™ Boards

From £1.38 per linear metre (ex VAT)

Silva Select Western Red Cedar Corner Trim 43 x 43mm

Per Linear Metre:

£5.75

(exc VAT)

Western Red Cedar Battens 19 x 38mm

Per Linear Metre:

£1.69

(exc VAT)

Silva Select Western Red Cedar Solid Corner Trim 43 x 43mm

Per Linear Metre:

£5.75

(exc VAT)

SILVALarch™ Corner Trim

Per Linear Metre:

£2.13

(exc VAT)

SILVALarch™ Decking

From £3.79 per linear metre (ex VAT)

Ipé 1st Grade Smooth Decking 21 x 145mm

Per Linear Metre:

£9.99

(exc VAT)

Mandioqueira Smooth Hardwood Decking 21 x 145mm - FSC Certified

Selected lengths reduced by 20%

Yellow Balau (Bangkirai) Decking Smooth 21 x 145mm

Per Linear Metre:

£6.49

(exc VAT)

Yellow Balau (Bangkirai) Decking Smooth 21 x 145mm - FSC Certified

Per Linear Metre:

£6.49

(exc VAT)

Neolife Decking

Per Linear Metre:

£8.17

(exc VAT)

Western Red Cedar Cedardeck Select

Per Linear Metre:

£5.29

(exc VAT)

Cascadia Western Red Cedar Decking

From £3.61 per linear metre

Western Red Cedar Cedardeck Clear

From £7.77 per linear metre (ex VAT)

Western Red Cedar Clear Vertical Grain Decking

From £4.95 per linear metre (ex VAT)

Western Red Cedar Posts and Railing Components

From £1.73 per linear metre

Universal Decking Connector

£83.60

(exc VAT)

Deck Board Tie

£27.06

(exc VAT)

EBTY EBE007 Mini Hidden Deck Fastener Pack (175 per box)

£86.84

(exc VAT)

Countersunk Stainless Steel Deck Screws

£5.66

(exc VAT)

Trim Head Stainless Steel Screws

£3.04

(exc VAT)

Pre Cast Concrete Deck Pier / Deck Block

£9.99

(exc VAT)

Stand Off Post Base

£10.20

(exc VAT)

A21 Angle Bracket

£1.15

(exc VAT)

FIN/Trim Head Climatek GRK Screws

60% off all Climatek Screws

Timber Cladding

Timber Focus supply many different cladding profiles ranging from your standard feather edge to a rustic style waney edge and even a shiplap profile, in a selection of hardwearing and stunning materials.

Timber cladding also referred to as weatherboards or weatherboarding, can add an extra dimension to a building. Different woods can be ut...

Timber Focus supply many different cladding profiles ranging from your standard feather edge to a rustic style waney edge and even a shiplap profile, in a selection of hardwearing and stunning materials.

Timber cladding also referred to as weatherboards or weatherboarding, can add an extra dimension to a building. Different woods can be utilised for cladding products; they can either be treated or untreated. We offer timbers that can be used for both internal and external applications.

We supply both the standard weather boarding or heavier more robust cladding for longer lasting beauty and for use in heavily weather exposed areas.

Advantages of Timber Cladding

Main Advantages

It is a lightweight material with protective functions

It also has decorative design functions

It is quick to install

It reduces the size and cost of foundations

It is applicable over a wide choice of woods to suite all budgets

It has outstanding thermal properties

It has outstanding sound insulation properties

It is suitable for new build and renovation projects

It is easy to repair.

Aesthetic Advantages

It has an attractive grain and colour

It comes in various styles

It is easy to redecorate

Environmental Advantages

It is a renewable resource

It is sustainable

It has a low carbon footprint

It can be recycled up to the end of its life

Timber Cladding Profiles

Profiled cladding is suitable for both internal and external applications. Kiln dried cladding is used internally as it is less inclined to shrinkage or movement, while air dried cladding and fresh sawn profiled cladding is used for all external applications.

Cladding can be laid horizontally, vertically or diagonally with either overlapping or flush faces. More commonly, the timbers are laid horizontally.

Timber Cladding Customisations

We can customise our cladding based on the client’s specifications. Our customisation includes species, profile, fire retardant treatment, size and grade.

Species

For External Half Lap Cladding and External Shiplap Cladding:

Hardwood (Oak)

Softwood (English Larch)

For Feather Edge Cladding:

Oak

Larch

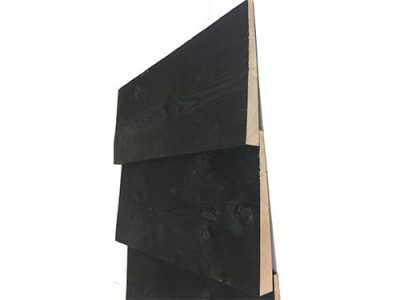

Black Painted Whitewood

For Fresh Cut Waney Cladding:

Oak

English Larch

Profile

External Profiles

Internal Profiles

Size

Available in random lengths. Customers can also modify these lengths with our custom cut service.

Grade

Our products come in two grades: Rebated Character Grade Oak and Character Grade V Tongue and Groove.

External and Internal Cladding

We offer both internal and external timber cladding in different profiles, lengths and dimensions.

Internal Cladding is available in the following timber:

Fresh Sawn Timber

Air Dried Timber

Kiln Dried Timber

External Timber Cladding falls into the Feather Edge Cladding category. Available in a sawn finish and supplied in random lengths between 1.7m to 3.6m, it can also be custom cut. This cladding option is available in the following woods:

Oak

Treated Softwood

English Larch

Timber Cladding Offerings

We stock a wide range of cladding products. All have been certified and have passed the necessary standards. Here are some of our offerings:

Profiled Cladding

Feather Edge Cladding

Rebated Feather Edge Cladding

Custom Cut Feather Edge Boards

Fresh Cut Waney Edge Boards

In addition, we also offer trim boards that are used as a finishing/edging to cladding projects. They are available in freshly sawn Oak or English Larch.

Timber Cladding Certifications

All of our products comply with the European QP1 standards and the THA or THB standards, as approved by TRADA (The Timber Research and Development Association). Sourced from various PEFC (Programme for the Endorsement of Forest Certification) and FSC (Forest Stewardship Council) accredited sources, our products are fully compliant with responsible felling methods.

Why are these certifications important?

They certify that merchants are against the destruction of the forest

They certify that merchants are in favour of forest management

They certify that the merchants offer high quality products

They certify that merchants have social and environmental qualities

More

Subcategories

By profile

The finish you require for your cladding project will not only depend on the species of timber you select, but also the profile. From a shiplap profile for those clean lines and structured appearance, to waney edge for that unique rustic finish, here at UK Timber Limited we offer a vast range of different timber cladding profiles to suit all tastes, budgets and projects in both residential and commercial settings.

By species

Choosing the correct species for your cladding project is of paramount importance. Not only do you want your finished project to be visually pleasing, but you will want to ensure that your cladding is offering you the right level of protection from the elements. Here at Timber Focus we offer a vast range of different timber species that suit all tastes, budgets and varying levels of weather resistance.

Trim Boards

These trim boards can be used as a finish and/or edging to cladding projects, soffits and facia boards.

Our trim boards are available in freshly sawn Oak and English Larch.

Cladding Screws

Here you will find cladding screws suitable for use with all of our hardwood and softwood cladding boards, both treated and untreated.

Cladding Treatments

At Timber Focus we offer a vast range of treatments and oils to help our customers get the most from their cladding. Whether you want protection from the elements to help with resistance against rot, decay and insect attack, or if you simply want to change the colour of your cladding to suit your current mood, our range of treatments and oils help make protecting and enhancing your timber easy. We work closely with the Treatex brand to ensure that our cladding treatments offer great value for money without compromising on effectiveness or quality.

Cladding Samples

13mm x 100mm Redwood Timber V1S PTG Matchboard

#12IC0500505

£1.64

19mm x 125mm 5th Redwood Timber PTG V Grooved 1 Side Matchboard Nominal

#12IC0500550

£2.72

25mm x 125mm 4th Redwood Timber PTG V Grooved 1 Side

#12IC0500555

£3.78

25mm x 125mm 5th Redwood Timber PTG V Grooved 2 Sides

#12IC0500556

£4.14

19mm x 125mm 4th Redwood Timber Shiplap Cladding

#12IC0550510

£2.66

19mm x 125mm Green Treated Timber Shiplap

#12IC0550615

£2.34

19mm x 125mm 4th Redwood Timber Weatherboard

#12IC0750515

£2.86

25mm x 150mm Arborclad Traditional Cedar Shiplap Timber Cladding

#04MHW410641

£10.10

25mm x 100mm Arborclad Traditional Cedar PTG Timber Cladding

#04MHW410642

£7.58

25mm x 150mm Arborclad Traditional Cedar PTG Timber Cladding

#04MHW410651

£10.98

25mm x 150mm Arborclad Traditional Cedar Offset Timber Cladding

#04MHW410661

£10.10

50mm x 50mm Arborclad Traditional Cedar Ext Corner Timber Mould

#04MHW410671

£8.76

22m x 155mm Arborclad Thermal Timber C6 Pattern Ash Cladding finished size

#04MHW410680

£9.89

20mm x 138mm Arborclad Thermal Timber Pine Offset Cladding finished size

#04MHW410681

£5.30

25mm x 125mm PTGV Tanalised Timber Jointed

#12XIC018038

£2.26

25mm x 150mm Arborclad Traditional Timber Larch Offset Cladding

#CLA00000003

£5.03

What is External Timber Cladding Boards?

Sometimes referred to as Weatherboarding, Exterior Timber Cladding Boards is a natural protection to the exterior of a property, that is designed to reinforce it from the elements. It can also help build up a buildings thermal and noise insulation.

The external wood cladding is most commonly manufactured from Timber which is a popular choice for both domestic and commercial properties.

Why is Cladding So Popular?

Timber has long had a reputation for being a high-quality, as well as an attractive solution. However, it is also popular because it is an environmentally friendly option that is sourced sustainably and 100% recyclable.

Types of Cladding

We offer a Traditional and Thermal Wooden Cladding range. The Traditional range includes:

Redwood

Larch

Western Red Cedar

The Thermal range includes:

Redwood

Spruce

Ash

Frake

Clear Pine

As members of the TDCA (Timber Decking and Cladding Association), Timber Focus is wholly committed to supplying the highest quality, sustainable timber cladding products, including innovative solutions such as the ArborClad range. Working with industry leading manufacturers alongside their own specialist manufacturing facilities, the ArborClad range is perfect for any application, from domestic and commercial to refurbishment.

Timber cladding is an increasingly popular choice for finishing the outside of commercial and domestic properties. Otherwise known as timber weatherboarding or timber siding, it is an attractive and economical way to finish the exterior of both old and new buildings. Naturally durable woods such as larch and cedar provide a hard wearing, protective layer against the elements and they are excellent insulators.

Many different species of wood are suitable for exterior timber cladding because of their natural resistance to decay. Traditional British timbers such as oak, elm, sweet chestnut, western red cedar and larch have been used as timber cladding for hundreds of years to protect houses from the elements. Imported timbers such as Canadian western red cedar and Siberian larch are increasingly being specified for cladding where a more modern, contemporary appearance is desired.

The various timber species we offer for cladding are available in a range of profiles from the more rustic waney-edge and feather-edge to the clean lines of machined shiplap and halflap.

Within this section you will find a wealth of information about selecting timber cladding species, board dimensions and profiles. You will also find pricing information to help you cost your cladding project as well as advice and diagrams to help you fix the boards correctly.

If you would like any further information about our range of timber cladding, or you require samples, please call or email and we will do our best to help.

Redwood Treated Shiplap Cladding Standard 19mm x 150mm Finished Size 14.5mm x 144mm

(649186)

£3.66 per metre

Redwood Treated Shiplap Cladding Standard 19mm x 125mm (Fin Size 14.5mm x 119mm)

(272639)

£2.95 per metre

Redwood Shiplap Cladding 19mm x 125mm (Finished size 14.5mm x 119mm)

(184002)

£3.08 per metre

Redwood Rebated Shiplap Cladding Std 25mm x 150mm Finished Size 20.5mm x 144mm

(184000)

£4.73 per metre

Travis Perkins Redwood Tongue and Grooved V Jointed Matchboard Standard 12.5mm x 100mm

(183006)

Shiplap Redwood Standard 19mm x 150mm (Finished Size 14.5mm x 144mm)

(184001)

Pine T&G Weatherboard 14.5mm x 144mm (Cover 137mm) - Scotland Only

(582039)

Timber Focus Softwood Shiplap Cladding 12x121x1800mm

From £3.68

Timber Focus General Purpose Softwood Cladding 14x94x1800mm

£12.06

Timber Focus Softwood Shiplap Cladding 12x121x2400mm

From £5.25

Timber Focus General Purpose Softwood Cladding 14x94x2400mm

£16.02

Timber Focus Fully Finished MDF Cladding 12 x 94 x 900mm

£2.14

Softwood Shiplap Cladding 12x121x1800mm

From £3.68

Timber Focus Softwood Shiplap Cladding 12x121x1800mm

From £3.68

Timber Focus General Purpose Softwood Cladding 14x94x1800mm

£12.06

General Purpose Softwood Cladding 14x94x1800mm

£12.06

Softwood Shiplap Cladding 12x121x1800mm

From £3.68

Timber Focus General Purpose Softwood Cladding 14x94x1800mm £12.06

Cladding

Timber cladding with a highly attractive and durable external finish

SILA A/B® 143 x 25, 100 x 25 and 42 x 25mm in vertical open rainscreen arrangement

Timber cladding provides a highly attractive and durable external finish which is renewable, reusable, biodegradable and contains minimal embodied energy.

Timber Focus have extensive experience in advising clients on material selection and careful detailing, which are key to ensuring that every project looks fantastic, and meets its performance objectives.

From our sawmill in the Scottish Highlands we manufacture cladding to each client’s specification, with a wide range of customisation options including: species, profile, fire retardant treatment, size and grade. We also have an in-house state-of-the-art coating facility, where we can vacuum coat cladding in the colour of your choice, in order to produce a consistent finish which will last.

In order to decide which species of cladding is most appropriate for your project, please go to the comparison table. You can then look at further details on each species by going to the product pages.

Cladding Products

Read more »

Scotlarch® Cladding

A selected grade of Scottish Larch which is locally-sourced

View product details Add to Lightbox

Read more »

Siberian Larch (SILA) Cladding

A popular choice due to its aesthetic beauty and excellent durability

View product details Add to Lightbox

Read more »

Thermopine Cladding

Thermally Treated Timber Cladding with enhanced stability & durability

View product details Add to Lightbox

Read more »

Vertical Grain Siberian Larch Cladding

Naturally durable and aesthetically refined

View product details Add to Lightbox

Read more »

Architect Select® Western Red Cedar Cladding

A beautiful, stable and naturally durable product

View product details Add to Lightbox

Read more »

Accoya® Cladding

A modified timber with outstanding dimensional stability

Product specification guide: advances in treatment and preservation are increasing timber’s sustainability

Timber Cladding

Timber cladding is more popular than ever – but how do you get it right? Our guide reveals all

Which Timber is Best?

Western redcedar is among the most popular softwoods used today. Aside from its relatively knot-free, ‘clean’ appearance, this softwood has a natural resistance to decay and moisture absorption, meaning it can typically be installed without treatment. It’s also the most stable of the softwoods, subject to little movement when installed.

If you did hope to apply a finish, its low resin content means it can be readily stained or painted. Added to this is the fact it can be worked to create a variety of profiles. But one downside is that it has a comparatively low density, which means it can be dented if knocked. It is imported from Canada and sometimes America, but increasingly grown here too (check the durability of the latter which can be a little lower than that of imported).

Whole life costing - Timber cladding

Timber cladding is an attractive and sustainable option

for external walls.

commonly available options and their whole life costs.

Introduction

Increasingly timber cladding is specified as the weathering envelope for walls. Timber is renewable, reusable, biodegradable and it has minimal embodied energy. This should be balanced against transport costs, the need to use chemical preservatives for some timbers and a shorter service life than material such as masonry.

There are many reasons why timber deteriorates, but the main cause of failure is fungal decay where moisture content within timbers is in excess of 20%.

BS EN 335 classifies the in-service environment for timber into five hazard classes to enable specifiers to assess how likely timber is to deteriorate in a given situation. External timber cladding is in Use Class 3 because its moisture levels frequently exceed 20%. This means some timber species will require preservative treatment. BS 8417, which covers the preservation of timbers, draws on a suite of European standards to enable selection of timbers and the type of preservative treatment necessary, for design service lives of 60, 30 or 15 years in different hazard classes.

• Timber's natural durability is determined to BS EN 350

• The need for treatment for different Use classes is determined to BS EN 460.

• BS EN 351-1 defines the penetration and retention needed to give a desired service life with a preservative treatment to BS EN 599.

The heartwood of timbers which are classed as ‘durable’, and ‘moderately durable’ do not need preservative treatment for external wall cladding. Timbers that are classified as ‘slightly durable’ do require preservative treatment. All sapwood require treatment.

Timbers not requiring preservative treatment

Western red cedar is a ‘durable’ timber from North America. It may be coated with oil to maintain its appearance, with the associated regular costs of recoating.

European Larch is ‘moderately durable’. UK-grown larch, larch from Siberia or regions where trees are slow-growing and older than 60 years have a similar expected service life with a similar age and growth pattern. The density of larch is between 470 kg/m˛ and 650 kg/m˛ at 12% moisture content. This gives larch a better resistance to impact compared with western red cedar, which has a density of 330-390 kg/m˛.

Douglas fir from North America is ‘moderately durable’. However. BRE Digest 494 recommends that UK-grown Douglas fir be classified ‘slightly durable’ and given preservative treatment.

European oak is a ‘durable’ hardwood. Oak is more expensive and needs to be specified carefully to minimise its tendency to warp. Shorter lengths are recommended as well as fixing shortly after being cut at the sawmill. Hardwoods may require fixing with screws through pre-drilled holes, which increases installation costs.

Timbers requiring preservative treatment

Spruce, Fir and Pine: These non-durable species require preservative treatment. Typically this will be by pressure impregnation of chemicals with preservative properties such as boron or organic solvents.

Thermally modified timber is an alternative to chemically treated timber. A controlled heat treatment to temperatures over 200°C confers improved durability and stability to timber, typically European redwood (Pinus sylvestris).Expected service life for thermally modified, uncoated timber cladding is 30 years.

Lodgepole pine from Canada is a ‘moderately’ to ‘slightly durable’ softwood, which is treated with preservative and coated in a high-performance paint system at the manufacturing plant. Expected period to first maintenance is 15 years and there after every 3 – 5 years.

European whitewood is a generic term that includes spruce and fir. These are ‘slightly durable’. Preservative treatment is required to give a service life 5 to 10 years. With a well-maintained paint system expected lives can be extended to up to 30 years.

Durability issues

Design strategies can enhance durability by reducing the risk of wetting and removing moisture promptly:

• Protect from rainwater with large eaves overhangs

• Terminate the cladding at least 150mm above ground levels, preferably 250mm

• Ensure cladding is not directly in contact with porous materials

• Include a well ventilated and drained cavity behind the cladding. This should be at least 19mm wide

• Moisture content of the timbers should be between 13 – 19% , less for heat-treated timber

• Seal end grain

• Allow sufficient gap between cladding sections to prevent capillary paths; 5mm is recommended

• Use stainless steel fixings

The Timber Research and Development Association and BRE provide detailed good practice guidance.

Timber Focus SUPPLY A LEADING RANGE OF TIMBER CLADDING AND FAÇADE SOLUTIONS.

We are a specialist manufacturer of wood cladding with over 40 years of experience. All of our timber cladding products are produced in the U.K or through our partner in Switzerland Sweden Estonia the range includes

MicroShades ‘Brunnea’ Redwood Timber Cladding

MicroShades ‘Brunnea’ Redwood Timber Cladding

PEFC/ FSC Certified

Imported from Scandinavia

Typical lengths from 2.1m – 4.8m+

Available in 3 live knot grades (A+, A, B)

MicroShades ‘Brunnea’ Western Red Cedar Timber Cladding

PEFC Certified

Imported from Canada

Many boards supplied are clear of knots

Available in 2 live knot grades

Imported Siberian Larch Timber Cladding

FSC Certified

Imported from Russia

Typically 4.0m lengths

Available in 3 live knot grades (A+, A, B)

Canadian Western Red Cedar Timber Cladding

PEFC Certified

Imported from Canada

Many boards supplied are clear of knots

Available in 2 live knot grades

UK/ Homegrown Larch Timber Cladding

FSC Certified

Grown in the United Kingdom

Low Carbon Footprint

Faster grown than imported species, large and frequent knots along the length

UK/ Homegrown Western Red Cedar Timber Cladding

FSC Certified

Grown in the United Kingdom

Low Carbon Footprint

Faster grown than imported species, large and frequent knots along the length

Swiss Painted Timber Cladding

FSC Certified

Swiss White Fir

Premium coatings applied, warranties available

Sioo:X Coating

Sioo:X is a safe, natural and sustainable technology for the protection of wood both outdoors and indoors.

Applied in house via automated Spray Line

Scroll through the images for our weathered and newly coated examples.

| |

Overview of Timber Focus (the home of Natural Timber Cladding in the UK) supply:

Timber Cladding including Western Red Cedar Cladding, Cedar Cladding and Cedar Shingles

Timber Focus , based in the UK, are nationwide suppliers of a complete range of Timber, including Timber Cladding products for weatherboading, and are specialist suppliers of Western Red Cedar Cladding , Western Red Cedar Decking, Western Red Cedar Shingles, Western Red Cedar Panels and Louvre Blades / Bris-Soleil systems, Cape Cod - Finished Wood Siding, Western Red Cedar Shingles for roofing and cladding, Siberian Larch Cladding, Thermowood for Cladding, Decking, Louvre Blades and Brise Soleil, Sweet Chestnut for decking and cladding, Accoya ® sidings and facades, Accoya decking (ACCOYA ® and the Trimarque Device are registered trademarks owned by Titan Wood Limited, a wholly owned subsidiary of Accsys Technologies PLC, and may not be reproduced without written permission.), Timber Louvres, Home Grown Larch Cladding, Hardwood Cladding, European Oak for external cladding, Douglas Fir, Cumuru, Red Louro,Protac Sivalbp, Parklex Facade, Cedar Shingles & Cedar Shakes, Oak Shakes and Chestnut Shakes.

Timber Focus are a major UK Timber Cladding supplier of weatherboarding, Red Cedar, Cedar Shingles and Cedar Shakes on a nationwide basis.

Timber Focus can provide timber which is fire retardant under classifications of Euroclass B and Euroclass C, factory coated opaque or translucent stain with treatments from Sikkens, Omnia, Morrells, Sigma and Zobel.

Vincent Timber supply timber to a very wide range of users and we work very closely with Architects. Some of the main markets sectors to which we supply timber are the Building Industry, Exhibition Stand Contractors, the Packing Industry, the Trailer Manufacturing, Commercial Vehicle Bodybuilding and Haulage Industries where the vehicle bodybuilders use Phenolic plywoods, Metal Faced plywoods, slip resistant plywoods and keruing flooring.

Timber Focus is at the fore-front of the campaign to protect the environment as illustrated by the fact that the company was only the 2nd company in the UK to be awarded Chain of Custody for CSA and SFI to cover Western Red Cedar. Timber Focus are members of TRADA and have appointed them as the company's auditors and advisors on their implementation of their "Chain of Custody". Currently, Timber Focus has Chain of Custody for: FSC® (Forest Stewardship Council) PEFC (Programme for the Endorsement of Forest Certification) CSA (Canadian Standards Association) and SFI (Sustainable Forestry Initiative).

|

Timber cladding has been used for centuries due to its durability.

Choose from a range of attractive external cladding profiles (shapes) to achieve a range of looks on your building from traditional to extremely modern.

Western Red Cedar Feather Edge Claddin

Canadian Western Red Cedar Feather Edge Cladding has very few knots and a mixture of colours. It is extremely durable.

estern Red Cedar Tongue and Groove Cladding

Canadian Western Red Cedar Tongue and Groove is a mixture of reds, browns and creams with very few knots.

Western Red Cedar Shiplap Cladding

Canadian Western Red Cedar has warm reds, browns and creams with few knots and uniform, straight lines.

Western Red Cedar Rainshield Cladding

Imported Canadian Western Red Cedar Rainshield Cladding is extremely durable with a mixture of warm, red and brown colours.

Product Description

What’s the secret behind Canadian Western Red Cedar Cladding’s popularity?

"In short, Canadian Western Red Cedar Cladding is good value, looks great and can last a lifetime."

Instant prices for cladding and secure online checkout. It’s obvious that the building industry is picking up again. Sales of Western Red Cedar Cladding are climbing at a fantastic rate. Why is it so popular?

In short, Canadian Western Red Cedar Cladding is good value, looks great and can last a lifetime.

Cedar, a softwood, is highly resistant to decay, as well as resistant to splitting and movement once fitted.

Canadian Western Red's Colour

When first installed, this timber cladding is a warm reddish-brown colour. If left untreated, it turns the classic silver colour over a number of years, depending on how much direct sunlight it receives.

Red Cedar's Service Life

With regards to durability, Red Cedar, without any form of treatment, has been known to last up to 60 years!

Cedar Cladding Quality

Timber Focus Western Red Cedar is machined to order. The grade, “Clear and Better” is the highest grade of cedar that we can source. There are virtually no knots and if there are any, they will only be small.

Thee profiles are available

to buy above

Timber Cladding Profiles

Timber Focus offers 10 different cladding profiles.

From our range, the Tongue and Groove machined profiles are the most popular timber cladding, particularly ICW1, closely followed by Rainshield. The machined profiles give a modern look to a traditional material. The machined profiles are supplied in lengths between 2 and 4 metres.

The fresh sawn Feather Edge profiles allow for your choice of overlap and are therefore the most flexible at the time of fitting. This cladding is supplied in lengths of 2.44m (8') and longer.

Western Red Cedar Pricing

For the benefits it offers, this timber is very competitively priced. If you click the price comparison button, you’ll see that there are cheaper timbers available, but none of them have the durability of the cedar.

Timber Focuses Timber's Product Code for this item is IW-18-24. A grade-specific code can be found below.

From: £5.41 per metre (Feather edged, logged in for discount)

Available from: Timber Focus Condition: New, supplied to your requirements. Availability: Available for order.

Timber Cladding

With timber being increasingly specified as the material of choice for exterior and interior cladding, we would like to show you some of the great range that Timber Focus can offer.

Timber Focus offers a range of timber cladding providing an attractive, versatile and durable external finish. With its excellent environmental credentials timber is increasingly becoming first choice for cladding.

Why use Timber for Cladding?

Appearance

Not only does it look good, enhancing the external appearance of any building, it makes it more interesting and pleasing to the eye. The versatility of timber means it can be produced to almost any requirement. With ageing and weathering, timber gradually changes colour to an attractive silver-grey. Alternatively it can be treated or stained to individual taste.

Durability

Some hardwoods and softwoods such as Western Red Cedar, Larch and Douglas Fir are naturally resistant to decay. Less durable species such as European Redwood can be preservative treated to prolong life in service.

Performance

Along with durability and a long service life, timber cladding’s natural properties offer improved acoustic and thermal conductivity performance.

Timber cladding is attractive, versatile, environmentally friendly, allows for great creativity, flexible in design and can be used for any scale of project.

Every branch of Timber Focus , along with its timber division, Timber Focus was awarded Chain of Custody certification through BM TRADA-TRAK in November 2018. This enables us to offer you fully certified FSC® and PEFC on an ever increasing range of products, and covers softwoods, hardwoods, sheet materials and engineered wood products.

Our Chain of Custody certification underlines Timber Focus’s commitment to the environment. The company continues to work with all suppliers with the aim of expanding this portfolio, and is fully committed to the Responsible Purchasing Policy.

At Timber Focus our stocked claddings are from European Redwood (Pine) or European Whitewood (Spruce), but from time to time the Architect may specify a more specialised species of timber cladding like Western Red Cedar, Siberian Larch or Thermowood. Taking this into consideration we would like to give you an insight into all these alternatives, explaining the features of each.

Scandanavian Softwood Cladding

European Redwood and Whitewood are perfectly suitable for interior cladding and external cladding when treated with timer preservative, paint of stain.

Western Red Cedar

WR Cedar is usually imported from Canada, and is available either Kiln Dried or Green (sometimes referred to as Air Dried) and is mainly used for Shiplaps, Channel Cladding, Tongue, Grooved and ‘V’-jointed Matching or PAR. You can also get a British Grown alternative version that will be predominately Fresh Sawn, which is faster grown and is mainly used for Featheredge or Waney Edge Boards. One of the prominent features of WR Cedar is its colour variability ranging from cream through salmon pink to dark chocolate brown and all shades in-between, it may also alternate from light to dark zones across the board. This colour will fade over time to a silver-grey colour when exposed to moisture and ultraviolet light; this is often referred to as weathering ±.

Because these products are Durable no further treatment will be required, the exception would be for Fire Retardant treatments such as Non-Com or Dri-Con (or alternatives like Fire-X and FirePro). ± To reduce the silver-grey colouring effect of moisture and ultraviolet light an application of a surface finish that includes a pigment, which may be translucent or opaque, will help maintain the natural colour longer. An opaque finish will provide the best protection. This will need to be part of on-going planned maintenance performed on the cladding.

Siberian Larch

Larch is usually imported from Siberia to Mongolia and Northern China, and is available Kiln Dried and is mainly used for Shiplaps, Channel Cladding, Tongue, Grooved and ‘V’- jointed Matching or PAR. You can also get a British Grown alternative version that will be predominately Fresh Sawn which is faster grown and is mainly used for Featheredge or Waney Edge Boards. Due to the high resin content it needs to be dried slowly, the loss of resin can still happen even after installation. Because it is prone to splitting it is advisable to pre-drill pilot holes for any fixings (especially near to the edges and ends of the boards), which are recommended to be stainless steel to help avoid rust stains.The heartwood of the Larch is pale red-brown to brick red in colour, with clearly marked annual rings. This contrasts sharply from the sapwood that is narrow and lighter-coloured. This colour will fade over time to a silver-grey colour when exposed to moisture and ultraviolet light; this is often referred to as weathering ±.

Thermowood

Thermowood D Redwood and Thermowood D Whitewood are mainly used for Shiplaps, Channel Cladding, Tongue, Grooved and ‘V’-jointed Matching or PAR. Thermowood has a dark appearance and the aroma of burnt wood, this is a consequence of the high temperature the timber is subjected to (up to 212°C). The process causes the timber to become brittle and it may also have some end splits, face checks (especially down the pith), and some cracked/broken knots. This colour will fade over time to a silver-grey colour when exposed to moisture and ultraviolet light, this is often referred to as weathering ±.

Timber Cladding Frequently Asked Questions

- What is Timber cladding?

A. Also known as Weatherboards, Timber cladding offers an attractive, environmentally friendly and natural finish to the exterior of a property.

Q. What are the benefits to Timber Cladding?

A. Timber Cladding is becoming more and more popular thanks to it being an attractive, durable and environmentally friendly product which can also improve noise and thermal insulation of the building. The lightweight nature of Timber Cladding also makes installation quick and effective when compared to more traditional methods.

Q. What cladding options do Timber Focus offer?

A. Timber Focus offer a great range of exterior and interior cladding including Scandinavian Softwood, Western Red Cedar, Siberian Larch, European Oak as well as Thermowood and Accoya Wood to mention just a few – contact your local branch to discuss your cladding needs.

Q. Do you offer preservative treatments or fire protection for the Timber Cladding?

A. Yes, thanks to Timber Focus own timber preservation plants we are able to offer a number of different preservative treatments and fire retardant treatments. Find more information on the different treatments that are available

Q. What are FSC & PEFC?

A. FSC is the Forest Stewardship Council and the PEFC is the Programme for the Endorsement of Forest Certification. Both FSC and PEFC are committed to achieving the certification of forests to credible, independently verified standards of responsible forest management. Find more information on FSC and PEFC

For any other questions please contact us at info@timberfocus.com

Planed Timber Standard Redwood Shiplap 19 x 125mm Nom 14.5 x 120mm Fin

Product Code: T8401629

£2.55 Ex VAT per £3.06 Inc VAT per

Landscape Batten PAR eased 4 edges brown Treated 25 x 100mm

Product Code: T8405879

£3.17 Ex VAT per £3.80 Inc VAT per

Landscape Batten PAR eased 4 edges Green Treated 25 x 100mm

Product Code: T8405878

£3.17 Ex VAT per £3.80 Inc VAT per

Landscape Batten PAR eased 4 edges brown Treated 25 x 50mm

Product Code: T8405877

£1.57 Ex VAT per £1.88 Inc VAT per

Login for trade prices

Landscape Batten PAR eased 4 edges Green Treated 25 x 50mm

Product Code: T8405841

£1.57 Ex VAT per £1.88 Inc VAT per

Login for trade prices

Redwood Cladding Loglap 19x100mm Nom 15x94mm

Product Code: T8401500

£1.64 Ex VAT per £1.97 Inc VAT per

Bead/Butt MDF 9x2440x1220mm V313 MR Primed

Product Code: S7700180

£50.18 Ex VAT per £60.22 Inc VAT per

Bead/Butt MDF 9x1220x2440mm V313 MR Primed

Product Code: S7700179

£50.18 Ex VAT per £60.22 Inc VAT per

Type 2 Breather Building Paper Blue 1000mm x 100mtr

Product Code: BB012001

£95.85 Ex VAT per £115.02 Inc VAT per

TG&V Matching Cladding, 16 x 125mm Nom 11.5 x 120mm Fin

Product Code: T8405058

£1.69 Ex VAT per £2.03 Inc VAT per

TG&V Shiplap Cladding 16 x 125mm Nom 11.5 x 120mm Fin

Product Code: T8405059

£1.69 Ex VAT per £2.03 Inc VAT per

When Timber Focus timber cladding is uncoated, it will weather over time to a beautiful shade of silver-grey, providing a subtle, natural look which blends in to the natural environment.

All external building materials change over time, and wood is no exception. As it is a highly durable building material, cladding boards are expected to last for over 50 years but, during this time, the wood will age or, as it is known in the industry, weather. This weathering process will change the surface appearance of the boards and, potentially, the overall look of the building.

timber, irrespective of species, will eventually weather when exposed to its natural environment. As long as this is understood by architects, builders and clients, it can be considered as part of the overall project rationale.

The weathering process

When timber is exposed outdoors without a protective coating the surface undergoes rapid changes to both its appearance and its texture, as a result of exposure to both sunlight and moisture.

The first observable effect is often a temporary brown staining, as extracts in the timber rise to the surface where they oxidise. Sunlight then photo-degrades the wood surface and, along with moisture, enables stain fungi to grow and the timber surface to grey. The shade of grey will vary according to the duration and intensity of wetting. In parallel with this, the surface of the timber will roughen, with some check marks likely to appear. These effects, which are the result of sunlight, water, mechanical forces and heat, characterise the process of weathering.

It is important to note that weathering is a normal and healthy process in timber, and should not be confused with the fungal decay, which can sometimes be observed in timber cladding which has been incorrectly installed. Fungal decay is the result of extended periods of wetting, which have allowed fungi to break down the timber.

Timber, when correctly detailed, will weather beautifully, with its appearance varying dependent on the quantity of moisture on the surface (when it is wet, the timber will appear darker in colour).

Factors influencing weathering

Building location

In areas of high rainfall some timber cladding installations can turn grey in just a few months, whilst in drier areas the process is likely to be slower. Similarly, south-west facing walls weather relatively fast, due to their exposure to sunlight, whereas north facing walls tend to weather more slowly, but uniformly.

Building design

The design of a building also determines how it will weather, as the form and shape influences the impact that wind-driven rain will have on it. For example, buildings without eaves tend to get wettest at the top, particularly at the outer corners, so this may result in these areas weathering more quickly than other parts of the wall. If there are eaves then uneven weathering can occur (unless the eaves shelter the entire wall) as sunlight will be unable to reach the areas under these eaves.

There may also be areas which, due to the design of the building, are subject to splashing – this can also lead to the wood weathering faster in these areas.

Over time, the entire building (unless completely sheltered from the elements) will weather to the same colour, and will remain the same silver-grey colour for years to come

Timber species

As all Timber Focus cladding species are naturally durable, they can all be left to weather and will end up as a consistent shade of grey (unless the orientation or design of the façade prevents this). The only exception to this is Accoya® wood; which we would recommend vacuum coating in all instances.

Different species will weather at different rates, and result in slightly different shades, dependent on their durability and density properties. For further information about a particular species, please go to the product pages or speak to our technical team.

Prevention of weathering

Timber weathering is often viewed as a very attractive characteristic of timber cladding as it demonstrates that the product is natural and, over time, the silver-grey shade will allow the building to blend into its environment. The only way to avoid weathering is to apply a clear or coloured coating to the timber, which will require to be re-applied every few years over the life of the timber. Clear coatings will preserve the original colour of the timber, whilst coloured coatings can be applied in a colour of your choosing.

Timber Cladding Machined and Delivered Throughout the UK

We specialise in milling timber cladding and offer unrivalled quality, expertise and customer service. We can also deliver promptly to site giving accurate delivery times. We usually call customers as we get close to the address to keep them fully informed. We do not use couriers.

Timber cladding prices are based on quantity, please contact us for a very competitive quotation.

There are clearance offers priced from £25.00 per square metre.

HOME

ABOUT

TIMBER

Timber

Timber Focus are experts in imported timber from all around Europe and we also source sustainable home-grown timber from the United Kingdom. All of our timber has full chain of custody.

Cladding

Decking

ABODO

Fire Retardant

Post & Beam

ENGINEERED TIMBER

Engineered Timber

Our engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial applications. The products can be used for joists and beams that replace steel in many instances.

ULTRA joist

Bridge Construction

Feature Trusses

Glulam

TREATMENTS

SERVICES

Services

Timber Focus is a family own business for over 90 years and a leading supplier of timber. All of our timber has a full chain of custody and we can provide quality services such as CNC detailing, CNC moulding and finger jointing. No project is too small or too big for us; whether it be a self-build project or a commercial building, Timber Focus has the products, machinery, expertise and personnel to deliver a unique and quality end result

CNC Detailing

CNC Moulding

Fire Assessments

Finger-Jointing

CONTACT

Cladding

Home/Timber/Cladding

sustainable, cost effective, aesthetically pleasing

EXPERTS IN CLADDING INNOVATION

The choice of timber species available is as varied as the profiles. However, attention should not only be paid to the durability of the timber but, in particular, the detailing of the profile, as both need to be considered in order to ensure longevity of performance. Timber Focus can offer the following;

MULTIPLE SPECIES; Siberian Larch, Western red cedar, Sweet Chestnut, European Larch,Oak, Whitewood

Multiple profiles; standard and bespoke profiles TG&V

Rainscreen

SHIPLAP

HIDDEN NAIL

HALFLAP

FEATHER EDGE

SQUARE EDGE

LOGLAP 70mm

LOGLAP 44mm

LOGLAP 33mm

COLOUR COATINGS

Adding a protective coating such as colour will increase the longevity of your cladding. We can quote for any RAL colour of your choosing. Check out the protective oils exclusive to ABODO

UNIQUE SURFACE TEXTURES

Want your cladding to stand out when the sun shines down on it? Ask about our variety of free of charge additional surface textures that we can apply to the your cladding; ranging from smooth to hard

FINGER-JOINTING

Don’t want to spend hours on site cutting to the exact lengths and zero waste? The answer is our finger jointing service. Ask about this service where we can finger joint up to 12m lengths

Timber Focus has extensive experience in advising clients on material selection and careful detailing, which is key to ensuring that every project looks fantastic, and meets its performance objectives. If you require a species that isn’t mentioned please don’t hesitate to get in touch and we will do our best to accommodate your requirements

How to use Timber Cladding Effectively

Timber cladding has become a popular material with architects, designers and construction companies. It creates economic, sustainable, attractive and functional buildings that help drive innovation in building projects.

If you’re thinking of using timber cladding, it can sometimes be overwhelming looking through all the different options and possibilities. For more details on how to use timber cladding in your own building project, contact one of our experts today for a chat.

Before using timber cladding, it’s important to understand some of the opportunities available with such a material and how you can ensure you use cladding effectively.

So how can you use timber cladding effectively?

Take Advantage of cladding’s benefits

Timber cladding is a useful material for so many reasons. It is easy to machine and work with, which means it lends itself to creative and unique designs. If you’re thinking of using cladding, then why not get the help of an architect and take your building project to the next level.

Timber cladding is easy to machine so it is possible to create structures that utilize more curves and flowing shapes. This can help a building blend into its surroundings.

Use it to create and utilize space

Due to the ease of modification, timber cladding can be adapted very effectively. This means adding customised and personalised additions into a design is a lot easier and cheaper. This means that you can utilize timber cladding in more functional designs that solve a problem. If you’re working with limited space, cladding can help create more space. It isn’t difficult to add extensions and shapes coming out of the cladding to provide a more suitable design. This can provide extra storage or space which in turn can help create a building that is better suited for its end use.

This also makes cladding perfect for building extensions on established buildings. Cladding provides opportunities to build additional features to a home or building in a cost effective and simple way.

Ensure you pick the right kind of species and cladding type

To ensure you get the most out of your timber cladding and use it effectively, you need to make sure you have utilized the best type of cladding and timber species.

Different species of timber will behave slightly differently and there will be one type that is most suited to any given building project.

Western Red Cedar (below left) and Siberian Larch (below right) are examples of very popular species for timber cladding as they are easy to work with, don’t require preservative treatment and provide a sustainable material that lasts the test of time. For a full breakdown on the different timber species available,

Once you’ve decided on a timber species, you have the option to pick a specific type of cladding. Different cladding options will provide slightly different finishes to your cladding. Shiplap and Tongue and Groove are popular options as they are easy to install and provide professional looking cladding.

Protect and Maintain

It’s important to protect and coat the timber cladding to ensure it is protected against rot, moisture and insects.

There are a variety of different types of coatings that offer slightly different benefits and finishes. This will also affect the appearance of the cladding so it’s good to think about this in the planning and designing stages.

Don’t neglect what surrounds the cladding

To get the most out of any building material, it’s often worth thinking about how that material will sit with the surrounding environment. By paying attention to the detail and making sure the cladding works well with its surroundings, you can create something even more special.

Using materials that create a clear, bold contrast, or conversely, trying to use plants and trees to blend the building into nature, can help turn an average build into something that has a lasting impression on its local area.

Look at examples for ideas

Timber cladding has been used in construction for many years and there are lots of amazing examples of architects and builders using cladding in creative and innovative ways. By looking through these examples, you can get a better feel for all the different type of opportunities and possibilities you can achieve with timber cladding.

Final Thoughts

Timber cladding is a fantastic building material with plenty of scope to create innovative buildings. By ensuring you use timber cladding effectively, you can make sure you get the most out of your building and create something both stunning and functional.

For help in deciding how to use timber cladding effectively in your building project

Our website uses cookies and by using the site you agree to this.Learn more about cookies and how to manage them here.

Customer supportRegisterSign in

Menu

Ideas & Advice

StoresFind a Store

Search

Basket

Top of Form

Bottom of Form

1 hour Click + Collect Restrictions apply

Free delivery on orders over £50Restrictions apply

45 day returns policy

Home

Building Supplies

Timber & Sheet Materials

Cladding

Cladding

Categories

See more Timber & Sheet Materials

Filters

Material

Spruce (20)

PVC (14)

Pine (1)

Edge Type

Tongue and Groove (19)

Sawn finish (2)

Type

Cladding (33)

Cladding batten (2)

Availability

Click & Collect (17)

In Store (17)

Home Delivery (10)

Price

£2.50 - £5 (2)

£5 - £10 (10)

£10 - £20 (11)

£40 - £50 (12)

Rating

4& up (3)

3& up (6)

2& up (7)

1& up (13)

View 35 products

Cancel

Cladding

Filters

35 products

Sort by

Filter

Material

Spruce (20)

PVC (14)

Pine (1)

Edge Type

Tongue and Groove (19)

Sawn finish (2)

Type

Cladding (33)

Cladding batten (2)

Availability

Click & Collect (17)

In Store (17)

Home Delivery (10)

Price

2.5-5 (2)

5-10 (10)

10-20 (11)

40-50 (12)

Rating

4 (3)

3 (6)

2 (7)

1 (13)

Smooth Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 10

(15)

£16

Double Bead Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 10

(2)

£16

Add to basket

Smooth Cladding (T)7.5mm (W)95mm (L)1800mm, Pack of 10

(1)

£12

Add to basket

Smooth Cladding (T)7.5mm (W)95mm (L)1800mm, Pack of 10

(1)

£12

Add to basket

Smooth Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 10

(16)

£16

Add to basket

Smooth Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 5

£7.42

View product

Smooth Cladding (T)7.5mm (W)95mm (L)890mm, Pack of 20

(2)

£12.73

Add to basket

Planed Cladding Batten (T)16.5mm (W)30mm (L)2100mm, Pack of 12

(2)

£13.06

Add to basket

Double Bead Cladding (T)7.5mm (W)95mm (L)1800mm, Pack of 10

(4)

£12

Smooth Cladding (T)7.5mm (W)95mm (L)890mm, Pack of 10

(2)

£6.37

Add to basket

Smooth Cladding (T)7.5mm (W)95mm (L)890mm, Pack of 10

£6.37

Add to basket

Cladding (T)10mm (W)250mm (L)2400mm, Pack of 4

£42

View product

Cladding (T)10mm (W)250mm (L)1200mm, Pack of 8

£42

View product

Cladding (T)10mm (W)115mm (L)2400mm, Pack of 5

£16

View product

Smooth Cladding (T)7.5mm (W)95mm (L)1800mm, Pack of 5

£5.87

Smooth Cladding (T)7.5mm (W)95mm (L)1800mm, Pack of 5

£5.72

Smooth Cladding (T)7.5mm (W)95mm (L)890mm, Pack of 5

£3.15

Smooth Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 5

£7.42

Cladding (T)10mm (W)250mm (L)1200mm, Pack of 8

£42

Smooth Cladding (T)7.5mm (W)95mm (L)2400mm, Pack of 5

£7.62

Cladding (T)10mm (W)250mm (L)1200mm, Pack of 8

£42

Cladding (T)10mm (W)408mm (L)2400mm, Pack of 3

£42

Smooth Cladding (T)7.5mm (W)95mm (L)890mm, Pack of 10

£6.98

Cladding (T)10mm (W)250mm (L)1200mm, Pack of 8

£42

890mm cladding

Geom cladding

plywood hardwood sheets

roofing materials sheet

moulding mdf

cladding panels outdoor garden repair

C16 Treated carcassing timber (T)45mm (W)70mm (L)2400mm Pack

For constructional applications both internally & externally where a grade stamp is specified such as: house extensions, loft conversions, floor joists above DPC & suspended decking joists Treated to help prolong the timber's life and protect against rot or insect attack Slow grown & kiln dried to ...

View more

Geom Limestone Cladding (L)2400 mm (W)250 mm (T)10

10mm gap required between panel and light fittings Withstands temperatures up to 60°C Durable and will not discolour

View more

Hardwood Plywood Sheet (Th)5mm (W)1220mm (L)2440mm

This Plywood sheet can be used for Wall sheathing, flooring, roofing, general construction and renovation work Wall sheathing, flooring, roofing, general construction and renovation work When used externally all faces and edges should be treated with an appropriate preserver This product is included in our free ...

View more

MDF D shape moulding (T)6mm (W)30mm (L)2400mm

It is prefinished for quick and easy installation It is easy to fix using pins or adhesive depending on the end use A cost-effective solution to mend and cover rough edges and add a decorative touch to unfinished and ugly edges and corners

Exterior timber cladding and rainscreens

Exterior timber cladding is a popular facade that can add warmth to a building and provide a sustainable option over brick or alternative finishes. At Timber Focus, our exterior wall claddings include ThermoWood® cladding and softwood cladding.

Both our ThermoWood® claddings and softwood claddings are sourced from well managed and sustainable forests, are PEFC certified, and are available from stockists nationwide. To find out more about ThermoWood® and Softwood claddings and the available profiles, click on the options below.

ThermoWood® exterior cladding

Timber Focus ThermoWood® exterior cladding is produced by heat treating Finnish grown pine and spruce to temperatures in excess of 200 degrees centigrade. The resulting product is an altogether more durable and stable timber, an ideal material for use in exposed areas such as external wall claddings and rainscreens. At Timber Focus , we have a range of standard and special order profiles which are popular in commercial applications. View our ThermoWood Cladding profiles.

Softwood exterior cladding

Timber Focus Softwood exterior cladding is kiln dried for increased durability and machined with precision. This gives flexibility on the finish and style you want to achieve as it can be stained, varnished, painted and treated. At Timber Focus, we have a range of standard profiles to choose from. View our Softwood Cladding profiles.

Timber Cladding. At Timber Focus in Ireland all of our cladding is environmentally sustainable, low carbon, thermally efficent and aesthetically pleasing material that provides an effective decorative covering for external building facades and interiors.

×

Quick Order

Please open the website on a larger device to use the quick order functionality.

New rows are added automatically * Options Available Add to Cart

Home

About Us

Our Locations

My Account

€

Login / Register

Cart €0.00

0 items in your Cart

€0.00Checkout

My Account Order History My Favourites

Sign In | Register

Home

About Us

Our Locations

Browse Products

Building

Garden

Timber

Plaster & Insulation

Heating

Fixings

Sealants & Adhesives

Doors and Floors

Hardware

Roofing

Plumbing & Drainage

Hand Tools

Power Tools

Decorating

Bathroom & Tiling

Please define Product Class

Cart 0 items

Top of Form

Bottom of Form

Top of Form

Bottom of Form

Refine Search

Timber

Timber Cladding

Timber

Construction & Treated Timber (55)

Decking (52)

Timber Cladding (30)

Planed Machined Square Edge (48)

Skirting and Architrave (49)

Door Framing (32)

Sheet Boards (57)

Moulded Timber (49)

Window Board (22)

Stair Components (38)

Our Products

Building (356)

Garden (260)

Timber (432)

Plaster & Insulation (176)

Heating (246)

Fixings (386)

Sealants & Adhesives (81)

Doors and Floors (384)

Hardware (619)

Roofing (466)

Plumbing & Drainage (606)

Hand Tools (294)

Power Tools (389)

Decorating (329)

Bathroom & Tiling (203)

Please define Product Class (1)

Click & Collect Service >>

Order Online and Collect in Store

€ Price Promise >>

Best Price, Every Day, Every Customer ...

Stock Promise >>

Check available stock for collection or ...

Timber >

Timber Cladding

Timber Cladding

T&G Cabin Walling 193x47mm Treated 3.6Mtr

Item Code: 1290862

118 Available

Bulk Price from €13.37 ex VAT (€16.45 incl. VAT)

QtyAdd to Cart

T&G Cabin Walling 193x47mm Treated 4.8Mtr

Item Code: 1290876

107 Available

Bulk Price from €17.31 ex VAT (€21.29 incl. VAT)

QtyAdd to Cart

Barrel Board - Loglap Treated 120x17mm x 4.8 Metre

Item Code: 1286748

289 Available

Bulk Price from €7.11 ex VAT (€8.75 incl. VAT)

QtyAdd to Cart

Barrel Board - Loglap Treated 120x17mm x 5.4 Metre

Item Code: 1286754

16 Available

Bulk Price from €8.01 ex VAT (€9.85 incl. VAT)

QtyAdd to Cart

Barrel Board - Loglap Treated 144x30mm x 4.8 Metre

Item Code: 128666145

192 Available

Bulk Price from €12.32 ex VAT (€15.15 incl. VAT)

QtyAdd to Cart

Shiplap Cladding Board Treated & Smooth 144mm x 18mm 4.8M

Item Code: 12866548

430 Available

Bulk Price from €8.54 ex VAT (€10.50 incl. VAT)

QtyAdd to Cart

Western Red Cedar TGV Cladding 94x18mm 2.75Mtr (4x1" by 9ft)

Item Code: 1272011

380 Available

Bulk Price from €13.17 ex VAT (€16.20 incl. VAT)

QtyAdd to Cart

Western Red Cedar TGV Cladding 94x18mm 3.06Mtr (4x1" by 10ft)

Item Code: 1272012

48 Available

Bulk Price from €14.59 ex VAT (€17.95 incl. VAT)

QtyAdd to Cart

Western Red Cedar TGV Cladding 94x18mm 3.36Mtr (4x1" by 11ft)

Item Code: 1272014

106 Available

Bulk Price from €16.06 ex VAT (€19.75 incl. VAT)

QtyAdd to Cart

Western Red Cedar TGV Cladding 94x18mm 3.65Mtr (4x1" by 12ft)

Item Code: 1272015

207 Available

Bulk Price from €17.48 ex VAT (€21.50 incl. VAT)

QtyAdd to Cart

Red Cedar PAO 44x44mm 2.45mtr (2x2" x 8ft)

Item Code: 1272030

46 Available

€21.95 ex VAT (€27.00 incl. VAT)

QtyAdd to Cart

Red Cedar PAO 44x44mm 3.36mtr (2x2" x 11ft)

Item Code: 1272033

2 Available

€30.08 ex VAT (€37.00 incl. VAT)

QtyAdd to Cart

Red Cedar L Angle 44x44mm 2.44mtr (2x2" x 8ft)

Item Code: 1272041

19 Available

€21.95 ex VAT (€27.00 incl. VAT)

QtyAdd to Cart

Red Cedar L Angle 44x44mm 2.75mtr (2x2" x 9ft)

Item Code: 1272042

29 Available

€24.39 ex VAT (€30.00 incl. VAT)

QtyAdd to Cart

Siberian Larch TGV Cladding 94x18mm 3.05Mtr (4x1" by 10ft)

Item Code: 1272101

191 Available

Bulk Price from €8.13 ex VAT (€10.00 incl. VAT)

QtyAdd to Cart

Siberian Larch TGV Cladding 94x18mm 4.05Mtr (4x1" by 13ft)

Item Code: 1272104

400 Available

Bulk Price from €11.06 ex VAT (€13.60 incl. VAT)

QtyAdd to Cart

16

8

16

24

32

40

48

56

64

72

80

1

2

Next

Customer Services

Delivery Information

Returns Policy

FAQ

Click and Collect Information

Shopping Information

My Account

Our Locations

Privacy Information

Other Information

About Us

Rewards and Cashback

Store Opening Hours

Store information

Email sales@timberfocus.com

© 2018 Timber Focus Build & DIY Products All Rights Reserved

Timber Focus in Ireland Profiles

We provide a range of standard cladding profiles including secret nail (tongue and groove), face fix, shiplap and many others. If you cannot find the profile you are looking for here, contact a member of our sales team info@timberfocus.com

Timber Focus is the leading manufacturer and supplier of Timber Cladding in Ireland. We manufacturer our Cladding in our own factory and every board of cladding is CE Marked in accordance with EN 14915:2006 Solid Wood Cladding. We can machine a wide range of naturally durable species including Western Red Cedar, Siberian Larch, DuraWood, Accoya, European Oak and Iroko. Our range, most of which is either FSC™ or PEFC certified, has been carefully selected to ensure that it meets the highest standards of quality at the most competitive prices. We can also offer in-house services such as fire treatment and pre-treatments and pre-finishing.

Our Timber Cladding Showroom is available to visit (by appointment) where a full range of timber profiles and species can be viewed and the finer details of your project can be discussed with our Cladding experts.

Why use timber cladding?

Timber Cladding is a contemporary, yet classic solution to exterior building finishes. Few man-made materials can match the quality of beautiful and natural wood. Timber is a material that is both aesthetically pleasing and endlessly practical and is also the world’s only natural renewable construction resource. Timber cladding is a popular option where attractive appearance is important along with durability and resistence to weather. Corell Timber’s claddings are machined from Western Red Cedar, Siberian Larch, Accoya, Iroko, Heat Treated Softwoods & Hardwoods, European Oak.

Timber cladding offers designers a unique combination of practical, aesthetic and environmental advantages:

Practical advantages

It’s a lightweight material offering protective and decorative design functions

Dry installation means external envelope is quicker to install

Elimination of heavy masonry outer walls reduces size and cost of foundations.

Cladding panels may be factory pre-fabricated complete with insulation and breather membrane.

Wide choice of softwoods, hardwoods and modified woods to suite all budgets.

Performance easily enhanced by preservative treatment, wood modification, flame retardants and surface coatings

Outstanding thermal and sound insulation properties

Suitable for both new build and renovation projects

Ease of repair

Aesthetics advantages

Timber is a natural material, warm and comforting

It is attractive in grain and colour

Wide availability of styles, textures and finish options encourages design innovation.

Easily rejuvenated or redecorated

Environmental advantages

Timber is a renewable resource

Source certification schemes ensure its sustainability

Low carbon footprint – requires less energy to produce than any other construction material

Growing trees remove CO2 from the atmosphere. Using wood stimulates the expansion of managed forests to absorb more of this global warming gas.

Major potential for re-use or recycling at end of life

As climate change and CO2 reduction assumes growing importance in building design, timber cladding provides the ideal cost effective solution. Specifying timber has major environmental benefits over other materials

External timber cladding has been a well-established feature of buildings in the UK & Ireland and particularly Northern Europe for many centuries.

Traditionally, timber cladding has either been left unpainted and allowed to naturally weather; or been lovingly repainted every spring, as evidenced in the many picturesque towns and villages around the shores of the Baltic.

Today, timber cladding and facades are becoming increasingly fashionable in modern buildings, but the requirements of modern styles and building techniques demand a more adventurous colour palette combined with simpler and less frequent maintenance.